|

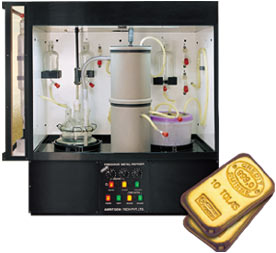

Precious Metal Refiner

Amrit Gem-Tech Pvt. Ltd.

has been bringing the latest international technology

for goldsmiths, to the Indian Gem & Jewellery industry.

Our services in the highly specialised field of automatic

chain manufacturing and investment casting are widely

acknowledged. Now for the first time in India with techinical

assistance from EMDICO (LONDON) LTD., U.K., we bring

you our very own automated refining system, the AMRIT

PRECIOUS METAL REFINER, in various capacities from 200gms

to 1 kg of 24k Gold.

|

|

The latest

international technology further improved. |

|

|

Refine all

your gold in your won premises under your total

control. |

|

|

Virtually

100% recovery. Very high purity can be achieved.

(999 or more) |

|

|

No highly

skilled labour required. Minimum handling of equipment.

Short process time, low operational cost. |

|

|

Refines carat

gold scrap, fillings, poloshings, dust, workshop

sweepings etc. |

|

|

Hazardous

fumes and odours, neutralised through gas treatment

system. |

|

|

Specially

designed filter barrel provides for quick filteration.

Traps all solids, even from thick slurry. |

|

|

Compact table-top

requires very little space. |

Based on the latest internationally

adopted method of refining, the AMRIT REFINER has incorporated

further improvements to suit the refining needs of the

Indian Jeweller. With our own research and development

facilities, indigenous manufacturing capability and

service network, we can provide proper training and

prompt after-sales service, besides providing specialised

consultancy for specific requirements of our clients.

Training in operation

of equipment and refining, provided at our factory prior

to despatch of the equipment, makes the AMRIT REFINER

very easy to use. The step by step instruction manual,

which comes with the system, provides further guidance

to your personnel.

All spares and consumables

are readily available in local market, no need to import.

With the AMRIT REFINER,

you can obtain fine gold from carat gold scrap, fillings,

polishings, dust, workshop sweepings etc., in your own

premises, under your total control, in a very short

time. This results in substantial savings, due to low

operational cost and complete recovery, withou paying

to outside refiners.

Precious metal is fully

recovered in powder form, ready for melting. Gold is

not left idle, but is refined and put to immediate use.

Hazardous fumes and odours

are neutralized before being discharged into the atmosphere,

maintaining a clean, healthy working environment.

Very little space is required

to start your own in-house refining.

The process consumes very

low electrical power 230 V, 50 cycles, single phase

electric (lighting) supply is required.

|